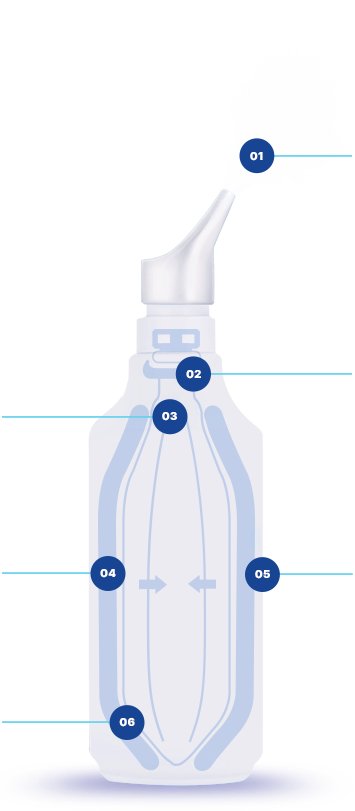

A device built for safety and security

1 The 100% seawater PHYSIOMER® solution, sterile and with no preservatives.

2 A one-way valve ensuring a guaranteed sterility during all shelf life of the product, even during occasional use.

3 A clear PET pouch of pharmaceutical quality containing the PHYSIOMER® sterile solution with no contact with the outside.

4 A natural rubber sleeve creates a mechanical compression of the pounch to obtain a gentle spraying.

5 A bottle with no propellant gas enabling a softer and child-friendly use, ideal for children and toddlers.

6 A lubricant facilitates the introduction of the rubber sleeve.

Our unique production process

-

01

Seawater collection

The seawater is collected from the waters off the bay of Saint-Malo and transported directly to Saint-Malo pharmaceutical facility.

-

02

Filtration

All impurities (planktons, sand, microorganisms, etc.) are removed from the seawater by filtration.

-

03

Electrodialysis

At this stage, the seawater still contains a high level of salt, which can harm the nasal mucosa. Electrodialysis removes these salts in excess without modifying the mineral content of seawater. The final solution has a salt concentration identical to that found in the human body (this is called an isotonic solution) or a greater concentration in the case of a hypertonic solution.

-

04

Sterilisation

This unique process, patented by Laboratoire de la Mer, guarantees the sterility of the solution without the need for preservatives or other chemicals that may be aggressive for the nose.

-

05

Filling of the bottles

The solution is now ready to be packaged into bottles. This step is performed in a sterile environment.

-

06

Packing

Regular quality controls are done throughout the production process, from seawater collection to product availability on the market. These control measures ensure a natural and high-quality product that meets the most stringent international standards (EC standards, sterile A label).

3 diffusions strenghts

Depending on the secretions type and patient symptoms severity. Depending on the type of secretions, symptoms of the patient and age. For a soft and child-friendly use, ideal for young children and toddlers.

Spray

Gentle diffusion for delicate noses

1,5ml/s

Normal jet

Abudant secretions

3ml/s

Strong jet

Purulant secretions

6ml/sA range for everyone

All the benefits of the sea for the gentle effective protection from daily nasal threats. Discover our 100% natural solutions for babies, children and adults.